Water Rocket Design Ideas For School Project – You can make this water rocket in a few hours (or less)! Water rockets use water and compressed air to launch soda bottle(s) 100 meters. This instruction does NOT apply to the launch vehicle. I hope to come back later and write a tutorial for the launcher. There are many websites with water rocket designs (and launchers). Part of the fun is experimenting and coming up with your own designs. Feel free to modify, improve, experiment with this tutorial and post your results in the comments. The original inspiration for the rocket comes from the magazine “MAKE Magazine” (makezine.com). Issue 5 also contains full instructions.

Please note: Depending on the brand of soft drink, there are slight differences in the openings of the bottle. Pepsi is slightly smaller than Coke. –

Water Rocket Design Ideas For School Project

This Instructable is set up for 2 liter bottles – you can adjust it to any size.

Outdoor Maker Lab Water Rocket Activity Pack

> 1 sharp knife (kids will ask your parents for help here!) I prefer the X-acto brand for cutting foam core.

> 1 large sheet of foam core (I prefer black, but any color will do). Foam Core can be found in almost any craft store. For more information about foam core, try Wikipedia: http://en.wikipedia.org/wiki/Foamcore

> 5 minutes Epoxy (This stuff is nasty! Do not inhale and use in a well-ventilated area. DO NOT get on skin, eyes, hair, etc…read all safety warnings before use.) Feel free to experiment with other adhesives. This can usually be found at any hardware store – kids, ask your parents about this glue.

Measure about a third of the way up the bottle and cut the bottle open. Try to keep the cut line as straight as possible. It may help to first draw a straight line around the glass. Make sure you recycle or use any waste items.

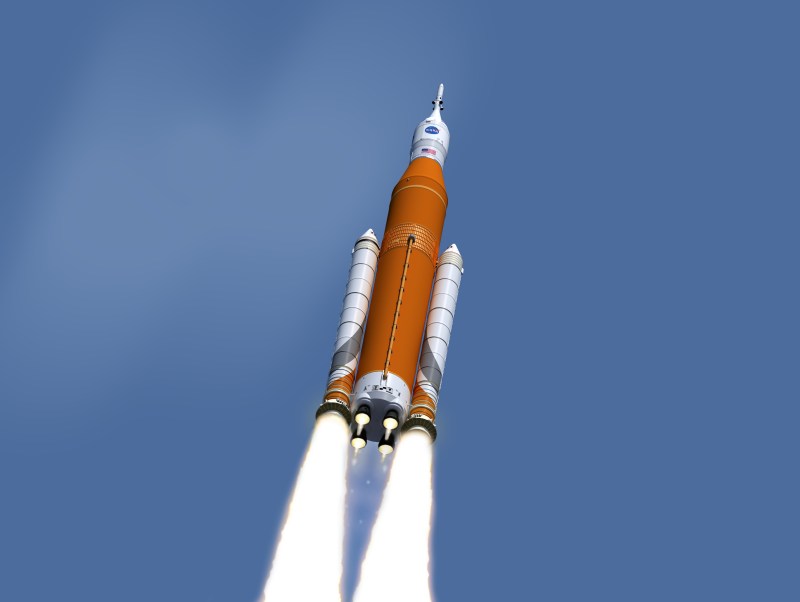

Vulcan Rocket Lifts Off For The Moon

Take the bottle you cut out from the previous step and place it directly on the bottom of the other bottle – this will be the rocket’s nose cone. Try to keep everything straight. If you tilt the nose, your rocket will fly at an angle. Place the nose cone on loosely first, then gently press it down until it is firm. Turn the bottle upside down and drop it on a hard surface several times. If you press too hard on the nose cones, they will “wrinkle” on the plastic. Wrinkles are bad.

Once the nose cone is securely (but not too tightly) attached, use clear duct tape to tape the seams. Try to keep a smooth ribbon.

Then you need to cut off some fins to make the rocket fly straight. I will try to upload a PDF file here that you can use as a template. I used a Pepsi bottle, so you may have to adjust the curves to fit the bottle. Children – this is the step where you need the help of your parents. Parents…cutting the foam core can be tricky. The point is to cut it once, with smooth movements. You have to press hard to ensure that the blade goes all the way through the foam core. If you feel more comfortable using a knife. Be careful!

Please! Experiment with your own fin designs. I opted for a more angular design, but if you want you can also use curves etc… I opted for 3 slats. You’ll need at least 3, but no more than 4 (unless you really want to!). If you do 3, you have to divide the bottle by 3, which equals 120 degrees. I’m trying to upload a second PDF file with a 120 degree template. 4 ribs, you only need 90 degrees.

Air Command Water Rockets Home

I cut 6 small triangles from some pieces of foam. (approx. 1 x 1.5 inches). These are added to the fins later for extra support.

Okay, here’s the tricky part. Open the glue (or glue of your choice). Squeeze out a small amount (enough to make a rib). Mix the epoxy with a piece of foam core (this will also be your “brush”). PREVIOUSLY mark the bottle (with the marker) where you want to align the fins. Make sure the ribs fit into the bottle BEFORE applying glue to them. Crop or adjust if necessary. Apply epoxy to the rib and attach it to the glass. WARNING: This step requires patience! 5 minutes is a long time. Figuring out a way to mount the clamps will give you more power. While holding the rib, do not move it… you can move and adjust the rib as the epoxy dries, but once it starts to harden it will be difficult to adjust. You will feel it starting to sink in. Once you reach the point where you can’t really adjust it anymore, you can place the bottles and fins on the table without holding them.

This is the next step of additional support. Pour another drop of epoxy and glue the triangle to the glass and rib. Glue the brackets to both sides of each rib. Wait about 10-15 minutes to make sure the epoxy has hardened.

I used BLACK and Bright Green to make it easy to spot the rocket in the sky!

How To Make A Bottle Rocket

Use the extra markers to add subtle details or words (I put H20 on mine so everyone knows it’s a water rocket). Add some pinstripes etc.

(Note: As you can see in this photo, I added extra tape to the ribs to strengthen them. Do this BEFORE painting.)

Maybe I should have mentioned this earlier, but this rocket doesn’t have a parachute! What goes up must come down.

DO NOT launch this rocket near people, crowds, small animals, streets or cars or houses… in other words… take your rocket to the middle of nowhere and launch it in a safe place. Make sure everyone knows that there is no parachute and that this rocket will fall to the ground at high speed. I don’t want him to hit me! The rocket will probably fly higher and further than you think.

Made My Husband A V2 Rocket With His Name On It

Youtube video of my rocket and some others from MAKE:PHILLY Bar-B-Que. (I’ll try to embed this video too). A combination of water, compressed air, and a plastic soda bottle makes a great source of propulsion for a backyard rocket (assuming you have a large backyard). Typical versions of these rockets involve gluing or gluing the nose cone and fins, which can be difficult to attach and will often be quite crooked and wobbly. Why not try a different approach to building a rocket frame around the soda bottle, instead of relying on attaching it directly to the glass?

First you need to understand the dimensions of the plastic bottle. A large set of calipers makes this much easier, but a ruler works fine with some patience. If you have to make a mistake anyway, bend it to the larger side, because the bottle will expand a little under pressure and you don’t want the frame to stick out or bend.

I converted these measurements into a series of reference rectangles. The height of each rectangle corresponds to the main vertical dimensions in the hand-drawn diagram. I placed a rectangle on top where the nose cone will be. I also added a rectangle to the side of the bottom where the fin will go. I decided to make the long part of the frame (which spans most of the length of the bottle) 0.5 inches wide, and that became the basis for the width of the other rectangles. If you look closely, you can see that these rectangles have a very rough outline on one side of the rocket.

You can now use the various intersections of reference rectangles to add curves. For most of the curves I used the simple 3-point curve tool. For the nose cone, the shape didn’t look quite right, so I used the B-Spline tool, which allows you to add more control points to the curve. This resulted in a smoother transition from the long vertical section to the nose cone, as well as the tip of the nose cone.

How To Make A Bottle Rocket

Once you have the shape you want, use the Clear Virtual Segment tool to remove unnecessary reference lines. If you haven’t already done so, change all the lines to red hairline lines to indicate that they are cutting lines and not engraving lines. The final step is to add an opening at the top and bottom where the support plates will go. This is where the vertical and horizontal parts connect to hold the whole thing together. I measured my cardboard and it was 0.15 inches thick, so I made my openings 0.16 inches wide so it wouldn’t be too tight.

The top horizontal piece consists of a circular disk with four sections